Site Work and Concrete Standards for Bollard Installation

Standard (Non-Rated) Bollards

Typical use cases include parking areas, sidewalks, storefront protection, and pedestrian guidance. The concrete primarily provides anchorage and long-term stability. Unlike most indoor bollards (e.g. in warehouses to protect areas against forklift damage) that are surface mounted, outdoor bollards are usually embedded into the concrete.

- Excavation depth: commonly 18–30 in. (adjust for frost line and soil). They can also be surface mounted with no below-grade component.

- Concrete strength: 2,500–4,000 psi compressive strength is typical; design and placement should follow ACI 318 principles for structural concrete.

- Slump: about 4–5 in. for workable placement in narrow holes or sleeves.

- Air entrainment: recommended in freeze–thaw climates (ASTM C260).

- Aggregate: normal-weight aggregate meeting ASTM C33.

- Finish: restore surrounding slab or pavement; ensure bollard is plumb and aligned.

PRO TIP: Expertly mixed concrete onsite will often only meet the minimum specifications for concrete strength.

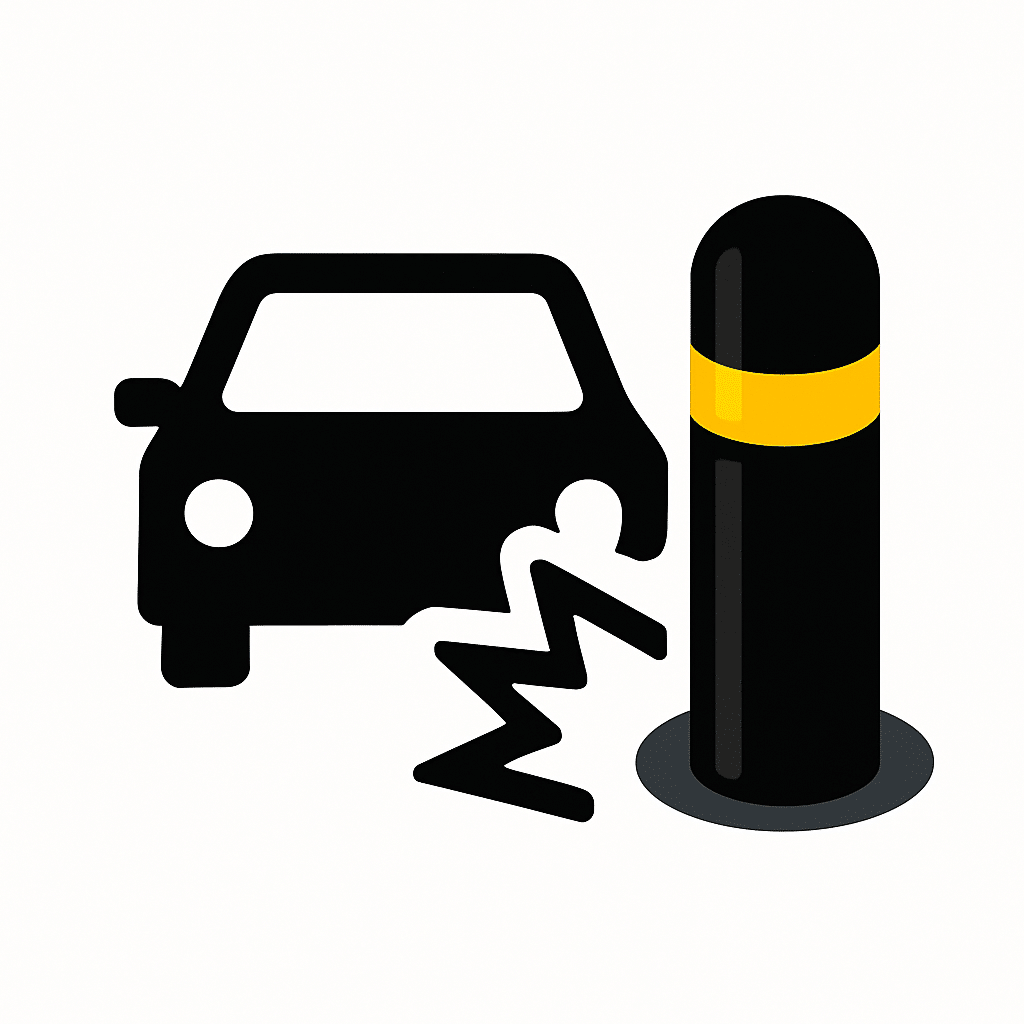

Crash-Rated Bollards

Crash-rated systems are tested to stop specific vehicle weights at defined speeds. Proper foundations and installation are essential to achieve the published bollard crash rating.

- Applicable test standards: ASTM F3016 (low-speed surrogate testing) and ASTM F2656/F2656M (full-scale crash testing of vehicle security barriers).

- Excavation & foundations: often 3–5 ft deep or more; many systems use continuous reinforced grade beams tying multiple bollards together.

- Reinforcement: rebar cages designed and detailed per ACI 318.

- Soil engineering: verify bearing capacity; weak soils may require over-excavation, engineered fill, or stabilization.

- Utility clearance: relocate shallow utilities out of the foundation footprint.

- Concrete placement & curing: place to avoid honeycombing; cure to reach specified strength before the barrier is considered operational (ACI 308R).

Concrete Mix Guidelines for Crash-Rated Foundations

- Strength: 5,000–6,000 psi design compressive strength (project specs may vary by product and soil conditions).

- Slump: 3–4 in. (use admixtures for workability instead of extra water).

- Admixtures:

- Water reducers / superplasticizers per ASTM C494 (Types A & F) to achieve strength and consolidation without excess water.

- Pozzolans such as fly ash (ASTM C618) or silica fume (ASTM C1240) for durability and reduced permeability.

- Fibers for crack control and toughness (ASTM C1116).

- Air entrainment for freeze–thaw durability (ASTM C260).

Why Standards Matter

Crash ratings assume the foundation is built to a specific specification. Deviations in excavation, reinforcement, mix design, or curing can compromise performance and negate a bollard’s crash rating. Following ASTM F2656/F2656M or F3016 (as applicable), together with ACI 318 for structural design and ACI 308R for curing, keeps the installed system aligned with the conditions under which it was tested.

References (Standards & Guidance)

-

- ASTM F2656/F2656M – Standard Test Method for Crash Testing of Vehicle Security Barriers.

- ASTM F3016 – Standard Test Method for Surrogate Testing of Low-Speed Vehicle Impact.

- ACI 318 – Building Code Requirements for Structural Concrete.

- ACI 308R – Guide to Curing Concrete.

- ASTM C33 – Standard Specification for Concrete Aggregates.

- ASTM C260 – Standard Specification for Air-Entraining Admixtures for Concrete.

- ASTM C494 – Standard Specification for Chemical Admixtures for Concrete.

- ASTM C618 – Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete.

- ASTM C1240 – Standard Specification for Silica Fume Used in Cementitious Mixtures.

- ASTM C1116 – Standard Specification for Fiber-Reinforced Concrete.

- FHWA Perimeter Security Design Guide (2018) – Federal Highway Administration guidance on vehicle barrier systems.

Project-specific drawings from the bollard manufacturer should always govern when they are more restrictive than the general guidance above.

About Post Guard

For over 23 years, Post Guard has been one of the largest manufacturers and suppliers in North America of bollards, bollard covers and crash rated bollards. Millions of our products have been installed and are protecting commercial properties everywhere. Learn more about Post Guard.